Refillable Steel Welded Gas Cylinder Reconditioning, Refurbishing & Testing Production Line

Also named: LPG Cylinder Manufacturing, Reconditioning & Refurbishing Equipments and Machines.

Liquefied petroleum gas cylinders, after prolonged use, may exhibit issues such as paint peeling, corrosion, mechanical damage (dents, scratches), valve opening difficulties, and gas leaks. Without regular inspections and timely refurbishment, these faults may shorten cylinder service life or cause accidents.

Why is it necessary to conduct periodic inspections on liquefied petroleum gas cylinders?

Common Knowledge about Inspection of Refillable Welded Steel Liquefied Petroleum Gas Cylinders.

Liquefied petroleum gas cylinders, after prolonged use, may exhibit phenomena such as paint peeling, corrosion, mechanical damage (such as dents, scratches, etc.), valve opening difficulties, gas leaks, etc. If not inspected regularly, timely detection and treatment of the above phenomena may result in reducing the service life of the cylinders or even causing accidents.

How is the periodic inspection cycle of liquefied petroleum gas cylinders determined?

Cylinders that are severely corroded, damaged, or have other defects affecting safe use should be inspected in advance. Cylinders in storage or out of use for more than one inspection cycle should be inspected before use. In China,according to the national standard GB8334-1999, for cylinders with a capacity of 15kg or less, the first to third inspection cycles from the date of manufacture are all 4 years, and the fourth inspection cycle is valid for 3 years. For cylinders with a capacity of 50kg, inspections are conducted every 3 years.

What is the purpose of the periodic inspection of liquefied petroleum gas cylinders?

The inspection of cylinders comprehensively evaluates their condition through effective technical means. For cylinders that meet safety technical standards, refurbishment of the external appearance and replacement of the easily damaged parts inside the valve are carried out. This can effectively protect the cylinders, prolong their service life, and ensure safety. Cylinders that do not meet safety technical standards are declared unusable and are destructively processed by the inspection unit to prevent them from entering the market and eliminate potential safety hazards.

Why can't scrapped cylinders be returned to customers?

If scrapped cylinders re-enter the market, they pose a danger not only to the users themselves but also to others. To prevent scrapped cylinders from being reused, regulatory authorities strictly control the handling of scrapped cylinders, specifying that they must be destructively processed by cylinder inspection stations and prohibiting their return to customers.

Why is it prohibited to pour residual liquid from cylinders by oneself?

Liquefied petroleum gas residual liquid is not like water as some may misunderstand; it has strong volatility and is highly flammable and explosive. Once it comes into contact with sparks or static electricity, it can easily cause fires or even explosions. Therefore, it is necessary to strictly prohibit pouring residual liquid by oneself. Customers in need can contact the filling station for disposal.

What are the procedures for cylinder inspection?

The designed annual inspection capacity of the detection line is 200,000–300,000 cylinders (calculated based on 12.5 kg liquefied gas cylinders). There are twelve procedures for cylinder inspection,the process flow is briefly described as follows:

1. Incoming Cylinder Registration: Cylinders awaiting inspection enter the workshop and are pre-registered and numbered. The cylinder records are documented, and inspection results are also recorded and stored in detail. Registered cylinders are placed in the waiting area for inspection.

2. Residual Liquid Recovery: Keep the cylinder's valve connected to a hose, and a residual extraction pump is activated to extract any remaining liquid or gas from the cylinder. The residual liquid and gas are separated, and the residual gas is directly sent to an incinerator for burning.

3. Valve Removal (Removed valves are sent for calibration): After residual extraction, the cylinders are transported to the valve removal station, where the valves are removed. The removed valves are then sent to a valve calibration bench for testing.

4. Cylinder Incineration: Cylinders without valves are placed on a conveyor line and transported into an incinerator for high-temperature burning. This process effectively removes residual paint on the outer surface and deposits on the inner wall of the cylinder.

5. Cylinder Cooling: The incinerated cylinders are conveyed to a cooling station for cooling, followed by a hydrostatic test.

6. Hydrostatic Test: Cylinders enter this station, where pressure is applied inside to test the stability of their performance. After the test, each cylinder is manually fitted with a specialized plug (which can also serve as a hanger for powder coating).

7. Rust Removal: Cylinders fitted with plugs enter the rust removal station for shot blasting, where high-speed steel shot from the blast head removes residual paint and rust from the outer surface through friction.

8. Spray Painting and Drying: Cylinders are hung on powder coating rings, and epoxy powder is sprayed onto them. Through electrostatic adsorption, a uniform layer of powder adheres to the outer surface. The cylinders are then sent into an oven for baking and heating, where the powder melts at high temperature and firmly adheres to the surface of cylinders.

9. Valve Installation (Installing calibrated valves): Cylinders that have been painted enter this station, where calibrated valves are installed.

10. Leak Test: Cylinders are connected to a gas source, filled with gas at the rated pressure, and submerged in a water tank to test the sealing of both the cylinder and the valve.

11. Cylinder Logo Printing: After passing the inspection, marking or logo is printed on the outer surface of the cylinders.

12. Vacuum Extraction: Air inside the cylinder is extracted by special machine.

Note: During inspection, any cylinders found to be defective must be sent for destruction. All defective cylinders must be destroyed using a scrap processor.

Included Equipment (Brief Intro)

The line includes specialized equipment for residual recovery, incineration, valve handling, hydrostatic and airtightness testing, shot blasting, powder coating, logo printing, vacuum extraction, and environmental protection units.

DB-YC-5 Residual Liquid Recovery Device

Closed-system recovery using a water-ring vacuum pump; meets GB8334-1999; separated gas sent to incinerator for combustion.

DB-FC-1 Residue Incineration Equipment

Atomizing combustion head + high-temperature furnace >= 500°C to ensure zero residual liquid and environmental compliance.

DB-YZX-1/15-50 Valve Mounting/Demounting Machine

Explosion-proof valve loading/unloading with torque protection and high efficiency.

DB-YFL-A LPG Cylinder Incinerator

Direct flame incineration for paint/rust removal; supports 11kg–50kg cylinders with automatic control.

QGY-4 Shot Blasting Rust Removal Machine

High-efficiency blast wheel & dual-roller conveyor: removes rust and optimizes surface for coating adhesion.

DB-SY-6/11 Hydraulic Testing Machine

Computerized hydrostatic testing unit suitable for LPG cylinder batch testing.

2D-SY100/10 Electric Pressure Testing Pump

Stable, multi-purpose hydraulic pressure pump for cylinder testing and deformation measurement.

DB-YQ-5/11 Airtightness Testing Machine

Compressed-air fill + immersion leak detection for cylinder & valve sealing inspection.

DB-PLS Electrostatic Powder Spraying Assembly Line

Electrostatic powder coating with hot-air circulation drying and automatic temperature control.

DB-YZ-1/11 LPG Cylinder Serigraphy Machine

Semi-automatic cylindrical screen printing for logos, marks, and safety information.

DB-YP-1/11 Scrap Cylinder Flattening Processor

Hydraulic flattening device for irreversible disposal of scrapped cylinders to prevent reuse.

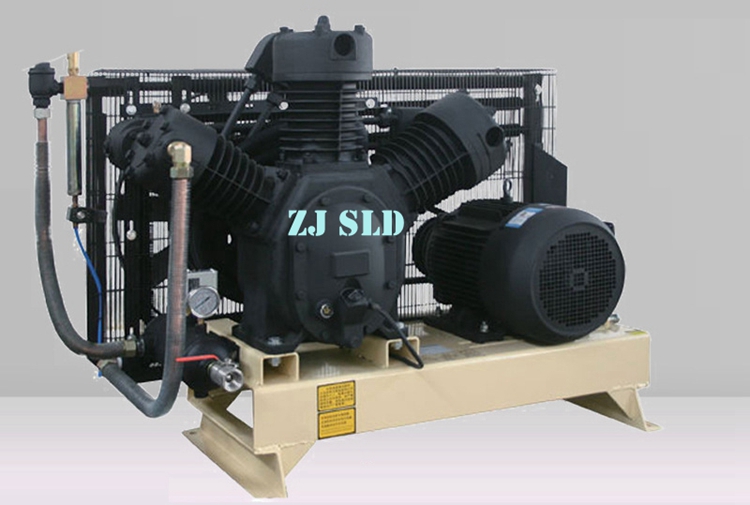

2.0/3.0 Medium-Pressure Air Compressor

Low vibration, patented valve design, long service life, stable air supply for testing stations.

1m³ / 30KG Medium-Pressure Air Storage Tank

Ensures stable medium-pressure air for hydrostatic & leak tests.

2m³ / 10KG Low-Pressure Air Storage Tank

Continuous low-pressure air supply for vacuum & leak testing operations.

3.4/0.8 Screw Type Low-Pressure Air Compressor

Screw-type compressor for low-pressure continuous operation.

2X-15 Vacuum Pumping System

Rotary vane vacuum pump for cylinder evacuation prior to filling. Not for explosive or corrosive gases transfer.

WM-18A Ultrasonic Thickness Gauge

Accurate measurement of cylinder wall thickness to monitor corrosion and remaining life.

HL-210 Combustible Gas Explosion Detector

On-site detection of combustible gas concentration for operator safety.

PZ27.8 Gas Cylinder Inspection Toolbox

Complete set of handheld tools and gauges for visual and mechanical inspections.

DB-YPX-5 Valve Calibration Platform

Calibration bench for removed valves to ensure correct torque, sealing and operation before reinstallation.

DB-FC-1 Incinerator Waste Gas Treatment

Waste gas treatment and waste-heat recovery system meeting emission standards; energy-saving & environmentally compliant.

The equipment used for testing LPG (liquefied petroleum gas) cylinders typically includes a range of tools and devices to assess various aspects of the cylinder's integrity, safety, and compliance with standards. Some common test equipment includes:

Hydrostatic Testing Equipment: This equipment is used to perform hydrostatic pressure tests on cylinders to ensure they can withstand the internal pressure of the gas. It usually consists of a test chamber, hydraulic pump, pressure gauges, and safety features.

Air Tightness Testing Equipment: Air tightness testing equipment is used to check for leaks in the cylinder and its valves. This can include methods such as pressure decay testing or immersion testing.

Visual Inspection Tools: Visual inspection tools such as borescopes and endoscopes are used to examine the interior surfaces of cylinders for signs of corrosion, damage, or other defects.

Ultrasonic Thickness Gauges: These gauges are used to measure the thickness of the cylinder walls to ensure they meet minimum requirements for safety and structural integrity.

Paint Thickness Gauges: Paint thickness gauges are used to measure the thickness of the protective coating on the exterior of the cylinder to ensure it meets standards for corrosion protection.

Valve Testing Equipment: Specialized equipment is used to test the functionality and integrity of the valves installed on the cylinders, including tests for opening and closing torque, leak tightness, and proper operation.

Marking and Labeling Equipment: Equipment for marking cylinders with identification numbers, manufacturing dates, inspection dates, and other required information.

These are just some examples of the equipment used for testing LPG cylinders. The specific equipment and testing procedures may vary depending on regulatory requirements, industry standards, and the type of cylinders being tested.