Digital Pulse Gas Protection Welding Machine

Digital Pulse Gas Protection Welding Machine For LPG Cylinder

Digital Three-Function Welding Machine

Function: Manual / Gas Protection / Pulse Gas Protection

Production Description:

1. X-in all digital soft switch inverter technology,good dynamic characteristics, high reliability, power saving and energy saving

2. There are 100 sets of accurate and authoritative databases in Z companies, which support the unified adjustment of 13 common metal materials, and the welding performance ranks the world's x-class level

3. The suitable metals are: carbon steel, aluminum, aluminum magnesium alloy, aluminum silicon alloy, stainless steel 307, stainless steel 308, copper aluminum alloy, copper silicon alloy, stainless steel flux core, acid carbon steel flux core, basic carbon steel flux core and φ powder cored carbon steel flux cored wire

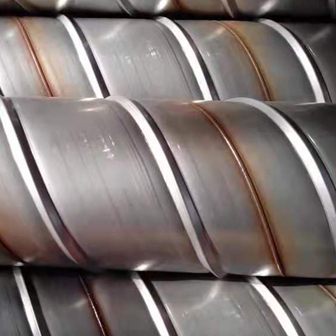

4.Pulse gas protection realizes one pulse and one drop truly,there is no spatter during the base value transition,and performs a good welding formation. It is especially suitable for the welding of aluminum alloy, stainless steel, copper alloy and other non-ferrous metals

5.X-in double pulse gas protection welding, on the basis of pulse gas protection welding, another pulse is superimposed, and the welder can weld the fish scale effect without swinging

6.It is the first one to integrate DeviceNet Fieldbus into the welding machine, which can be connected with most robots and special machines to realize welding automation

7.The wire feeder adopts double drive wire feeding with speed feedback function to ensure stable wire feeding speed. Parameters such as inching wire feeding speed, soft start speed, gas reservation and lag time, burn back time, arc starting and arc ending current can be set up

8. Centralized monitoring and control can be realized. It can also realize software upgrade and remote diagnosis, continuously record the date and time of each welding, parameter settings, welding current and voltage, arc break, short circuit, alarm and other conditions, so as to facilitate quality recording and control

9.Spot welding, 2T, 4T, special machine mode and aluminum welding mode, it is convenient to realize special machine welding and aluminum welding

10. Digital control, good consistency, stable performance, not affected by temperature, humidity and aging of components,It has protection functions such as overheating, overcurrent and overvoltage, and also has perfect self diagnosis function

Technology Details:

Specifications: 315,350,400,500,630

Rated current:10A~315A,10A~350A,10A~400A,10A~500A,10A~630A

Duty cycle: 60% 100%

Plate thickness: 1mm~25mm

Wire feeding speed: 1 m/min~22 m/min

Arc length: -50%~50%

Arc force: -50~50

Weldable material type: more than 13

Welding wire diameter: 0.8mm,1.0mm,1.2mm,1.6mm

Operation mode: 2T, 4T, S2T, S4T, Spot welding, JOB

Initial current (HoTI): 0%~200%

Arcing current (Endi) : 0%~200%

Initial time (Hott) : 0.1s~15s

Arc ending time (End) : 0.1s~15s

Burn back time (Burn): 0%-20%

Spot welding time (SPTT) :0.01s~2s

Double pulse frequency (Freq) : 0.5Hz~5Hz

Second arc length (AL2): -50%~50%

Double pulse amplitude (Fd2): m/min~2m/min

Transition time (SLOP) : 0.1s~15s

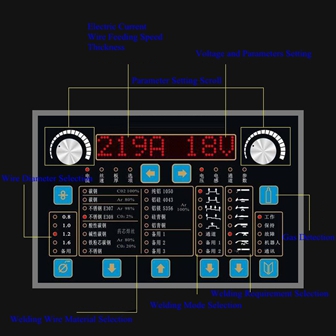

Main Characteristics:

1.Welding Mode Selection

2.Welding Wire Material Selection

3.Wire Diameter Selection

4.Gas Detection

5.Welding Requirement Selection

6.Electric Current,Wire Feeding Speed,Thickness

7.Voltage and Parameters Setting

8.Parameter Setting Scroll